3D Printing Hack for Starseeds: Free Tools, Makerspace Secrets & Sustainable Tips for New Futuristic Business Ideas

Table Of Contents:

Step 1: Embrace Free, Inclusive Design Tools

Step 2: Tap Into Community Makerspaces

Step 3: Download & Personalize Your Starter Design

Step 4: Slice with Sustainability in Mind

Print your purpose—start building your starseed solution.

Step 5: Execute, Refine & Finish with Care

Imagine…

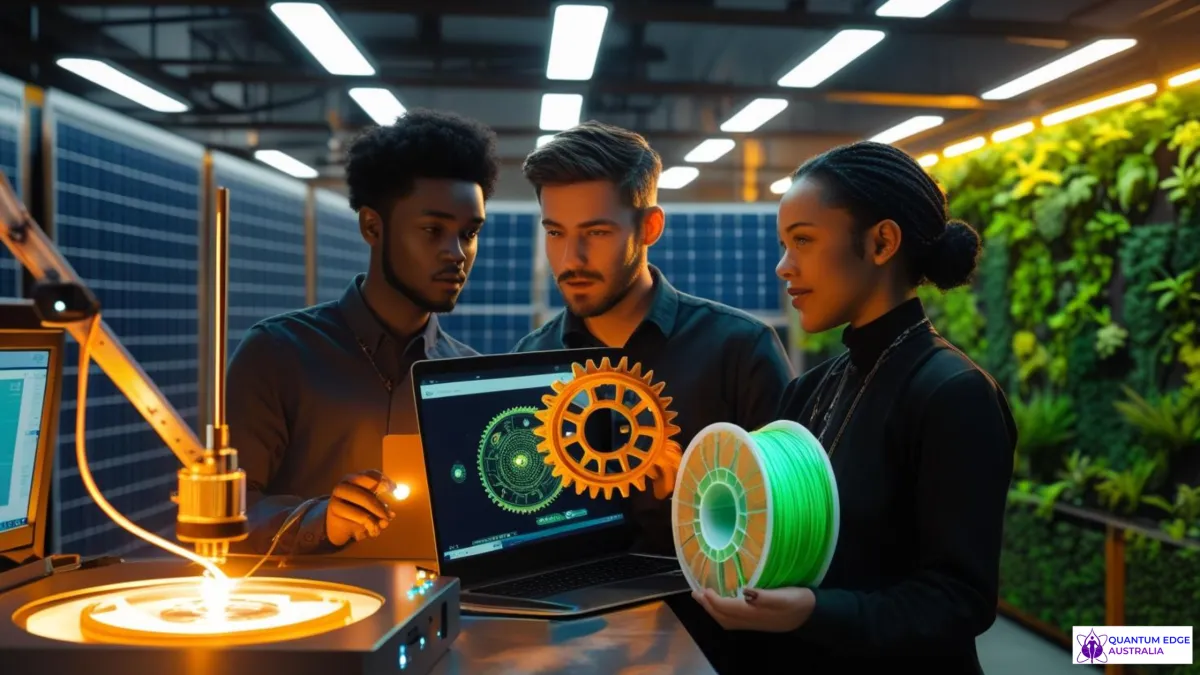

Stepping into a solar‑powered makerspace where your cosmic vision meets recycled‑plastic filament—watching your Cosmic Cog prototype rise layer by layer.

For spiritual Gen Z entrepreneurs crafting new futuristic business ideas, 3D printing is more than hardware: it’s a democratized, sustainable, heart‑infused launchpad. In this guide, you’ll discover free software, community lab strategies, eco‑friendly filament hacks, and our ready‑to‑print starter file—so you can print your purpose and spark real‑world impact.

Step 1: Embrace Free, Inclusive Design Tools

Tinkercad for instant browser-based modeling

Fusion 360 (free license) for parametric precisionDemocratization Insight: Studies show the Maker Movement, propelled by open‑source 3D tech, is reshaping innovation access worldwide 3dprint.comtascha.uw.edu.

Step 2: Tap Into Community Makerspaces

Find Yours: makerspaces.com or local library lab listings

Affordable Access: $5–20/hr memberships often include sustainable materials

Collaboration Culture: Swap prototypes, co‑host hack nights, join “Maker Faires” to share eco‑printing tips

Step 3: Download & Personalize Your Starter Design

Here are three excellent free designs you can grab right now to practice your 3D‑printing workflow—and make them your own with custom logos, dimensions, or eco‑grooves:

Parametric Spur Gear by Oskar

Why It’s Great: Fully customizable gear dimensions right in your browser via Thingiverse’s customizer tool. Perfect for learning gear parameters.

Imagine tuning the module and tooth count to sync two kinetic sculptures in harmony.

Planetary Gear Box by Maker’s Muse

Link: https://www.myminifactory.com/object/3d-print-planetary-gear-box-75094

Why It’s Great: An entire planetary gearbox in one download—ideal for prototyping functional drive systems for small robots or art installations.

Envision embedding a micro‑vibration motor inside for responsive biofeedback wearables.

Modular Mechanical Joint by GrabCAD

Link: https://grabcad.com/library/mechanical-universal-joint-1

Why It’s Great: A universal joint that snaps together—perfect for experimenting with moving parts and hinge tolerances.

Adapt this into a fold‑out arm for deployable solar panels—on Earth or in orbit.

How to Use These Files:

>Download the STL from any of the links above.

>Import into Tinkercad or Fusion 360, then add your logo, resize for your project, or carve lightweight lattice patterns for eco‑filament savings.

>Slice in Cura with 0.2 mm layers and 20 % infill—add a brim for the first layer.

>Print at your local makerspace, recycle your support scraps into future filament, and share your remix back to the community!

With these ready‑to‑go starter files, you can master marketable product development workflows and prototype faster than ever—no proprietary designs required.

Step 4: Slice with Sustainability in Mind

Slicer: Ultimaker Cura (free)

Settings: 0.2 mm layer height; 20% infill; enable “brim”

Eco‑Hack: Use the “Dynamic Infill” plugin to cut plastic waste by up to 30% arxiv.org.

Tip: Choose PLA from recycled sources or biodegradable blends.

Print your purpose—start building your starseed solution

Ready for deeper support? Join our Quantum Edge Collective to access guided workshops on sustainable prototyping and unlock the Quantum Innovations course.

Step 5: Execute, Refine & Finish with Care

Monitor First Layer: Ensure perfect adhesion—use glue stick or a reusable build surface.

Post‑Process Eco‑Style:

Remove supports gently; save scraps for future recycling.

Sand with 220‑400 grit; reuse sanding dust in experimental filament blends.

Seal with non‑toxic, water‑based primer.

Fact: Sustainable making is critical—waste from rapid prototyping can be cut by 50% with community‑scale recycling programs arxiv.org.

Additional Tips & Common Mistakes

Iterate Micro‑Prints: Short prints let you test form & fit—then scale.

Document Everything: Build a digital prototype diary in your Vision to Launch Coaching portal.

Avoid Perfection Paralysis: Ship functional over flawless—feedback fuels growth.

Join Open‑Source Feeds: Share your improvements on GitHub, Thingiverse, or our private forum.

Conclusion

3D printing is the nexus of new futuristic business ideas, sustainable innovation, and community empowerment. By leveraging free tools, eco‑minded slicing hacks, and our starter files, you’re poised to craft prototypes that honor both cosmic vision and earthly impact.

Print your purpose—start building your starseed solution